Carbon paste for the area for generating heat of XiCA Film Heater

- ㆍ Carbon black is mainly from C (Carbon) like Diamond and used for automobile, ink and cosmetics. During manufacturing processes, heat treated material from 1,000 to 3,000℃ named Carbon fiber and heat treated material over 2,500℃ named Graphite fiber

- ㆍ Graphite has higher Heat resisting characteristic compared to other material, lower thermal expansion coefficient, excellent thermal conductivity and electric conductivity and is widely used for the material for generating heat by electricity.

※ According to carbon and graphite mixing rate of carbon bend which is the part for generating heat of heating film, adhesive degree and resistance value can be adjusted.

- ㆍ The characteristic for the molecular structure of Carbon and layered sheets of Graphite is used.

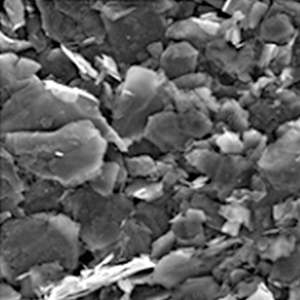

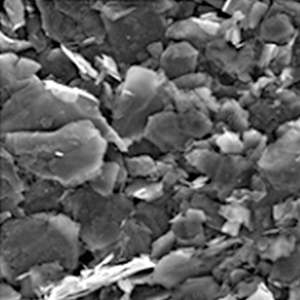

Graphite

Graphite

| First particle size |

5~25㎛ |

| shape |

Flate, square shape |

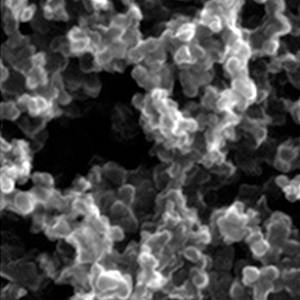

Carbon Black

Carbon Black

| First particle size |

50~100㎛ |

| Shape |

Spherical shape |

Carbon Paste

| Product name |

Carbon Paste |

| Composition |

Carbon, Graphite |

| Drying condition |

90℃ X 2min |

| Electrical resistance |

≤ 0.1 Ωcm |

| Features |

Good Adhesion on PET Film |

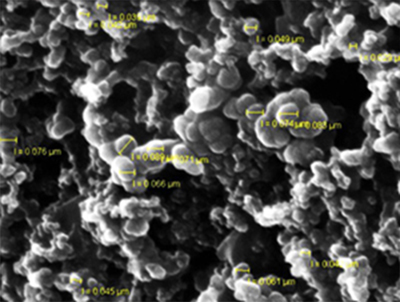

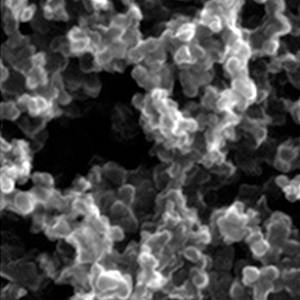

Particle size of carbon ink surface phase heating element and heating

| FE-SEM (magnification 120,000) analysis |

| Size range |

Size shape |

| 29~90nm |

Spherical powder shape |

Graphite

Graphite

Carbon Black

Carbon Black