QUALITY / SAFETY

Quality assurance system, competitiveness of RexVa!!

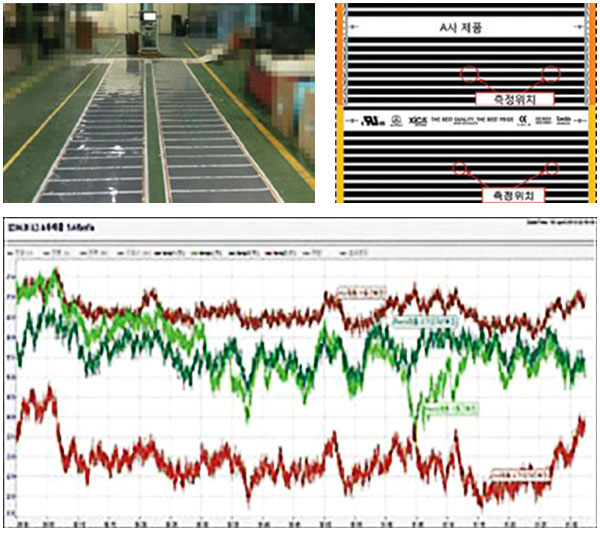

| Company | RexVa company | A company | ||||||

| Item | Time | Time | ||||||

| 3.30 | 4.00 | 4.30 | 5.00 | 3.30 | 4.00 | 4.30 | 5.00 | |

| Measuring temperature(sensor1) | 25.27 | 26.05 | 25.03 | 24.37 | 26.62 | 26.52 | 26.82 | 25.56 |

| Measuring temperature(sensor2) | 26.07 | 25.6 | 25.14 | 23.56 | 22.98 | 22.72 | 22.82 | 21.72 |

| Room temperature | 7℃ | 7℃ | 7℃ | 7℃ | 7℃ | 7℃ | 7℃ | 7℃ |

| Volt | 218V | 218V | 218V | 218V | 218V | 218V | 218V | 218V |

| Watt | 99.71W | 99.71W | 99.73W | 99.8W | 99.71W | 99.58W | 99.73W | 99.8W |

| Resistance | 438Ω | 338Ω | 338Ω | 338Ω | 438Ω | 338Ω | 338Ω | 338Ω |

| Infrared temperature measurement | 27.1/27.8 | 27.1/27.8 | 26.6/27.7 | 26.4/26.7 | 26.6/25.2 | 26.9/25.4 | 27/26.2 | 25.7/24.7 |

| Electromagnetic | 7/7 | 7/7 | 7/7 | 7/7 | 7.5/7.5 | 7.5/7.5 | 7.5/7.5 | 7.5/7.5 |

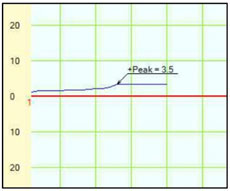

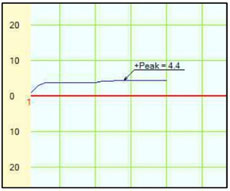

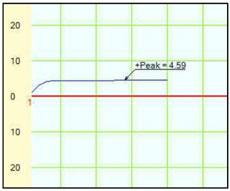

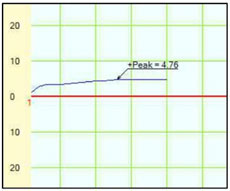

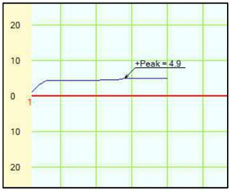

| Test | Tensile strength test | ||

| Model | XM305 | ||

| Test date | 2015.09.16 | Test No | T1-0006 |

| Reference value | 1st Test | 2st Test |

|

|

|

| 3st Test | 4st Test | 5st Test |

|

|

|

| Reference value | Tolerance | Average Value | 1st | 2st | 3st | 4st | 5st |

| 3.5 | ±0.5 | 4.68 | 4.4 | 4.59 | 4.76 | 4.78 | 4.9 |

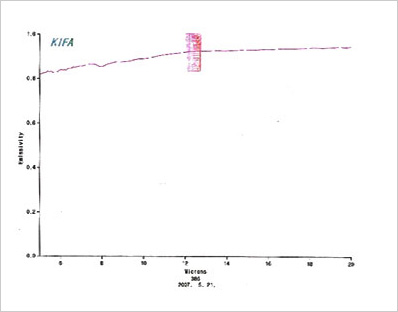

| Electromagnetic interference(K 00014-1) | ||

| Power supply terminal disturbance voltage | ■Pass □Default □N/A | |

| Interference power | ■Pass □Default □N/A | |

| Discontinuous power terminal disturbance voltage | ■Pass □Default □N/A | |

Measurement mode : 10 steps

*Test Information (find the voltage with the highest noise at 160KHz with voltage ranging from 0.9 to 1.1 times other than the rated voltage)

| Test voltage(V-) | 220 | 198(-10%) | 192 | 219 | 242(+10%) |

| LEVEL at 160 KHz(db(µw)) | 27.6 | 26.2 | 27.0 | 28.1 | 27.4 |

Measurement mode : 10 steps

*Test Information (find the voltage with the highest noise at 160KHz with voltage ranging from 0.9 to 1.1 times other than the rated voltage)

| Test voltage(V-) | 220 | 198(-10%) | 211 | 237 | 242(+10%) |

| LEVEL at 50 KHz(db(µw)) | 26.0 | 24.2 | 24.9 | 26.9 | 25.8 |

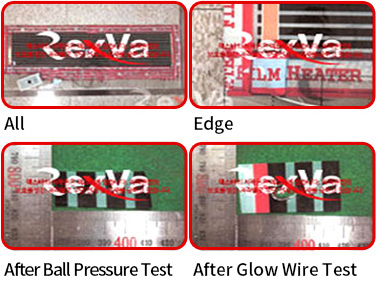

Europe applies the Low Voltage Directive (2006/95 / EC) for the safety of electrical products. The low voltage directive applies to all electrical equipment designed and applied for use between 50 to 1,000 V AC or 75 to 1500 V DC with a few exceptions. All manufacturers and importers who sell electrical equipment within this range are affixed with a CE mark on the product to verify that the product complies with the requirements of LVD and to demonstrate conformity.

| Requirement - Test | Result - Remark | Verdict | |

| 7.12 | - this appliance can be used by children aged from 8 years and above and persons with reduced physical, sensory or mental capabilities or lack of experience and knowledge if they have been given supervision or instruction concerning use of the appliance in a safe way and understand the hazards involved | Passed |

| 1st Test(Right) | 2st Test(Up) | 3st Test(Down) | |

| Foreign A Company | 12.4 | 6.8 | 3.6 |

| Foreign B Company | 13.1 | 7.3 | 2.7 |

| RexVa | 2.8 | 2.8 | 2.6 |

| Domestic A Company | 16.4 | 8.7 | 8.7 |

| Domestic B Company | 3.1 | 4.8 | 3.9 |

| Domestic C Company | 7.8 | 8.3 | 2.8 |

| Domestic D Company | 7.4 | 5.9 | 9.1 |

| Domestic E Company | 22.4 | 12.2 | 13.1 |

The CE mark is a European standard related to product safety, health, environment and consumer protection.

This means that all the requirements of the EU Directive are met, and products related to consumer safety distributed within the European Union must be approved and affixed with the CE mark.

Rohs is prohibition regulation for electric devices to limit usage of hazardou material such as Cadmium, chrome, flammable material, PB, Hg, PBB, PBDE in the products.

It has been announced in February 2003 by WEEE(Waste Electrical and Electronic Equipment) and this regulation has been valid since 2006 July 1st.