PRODUCT

PTC Heating Film Test Data

We are proud that the 3rd generation technology of Rexva is the best in the world.

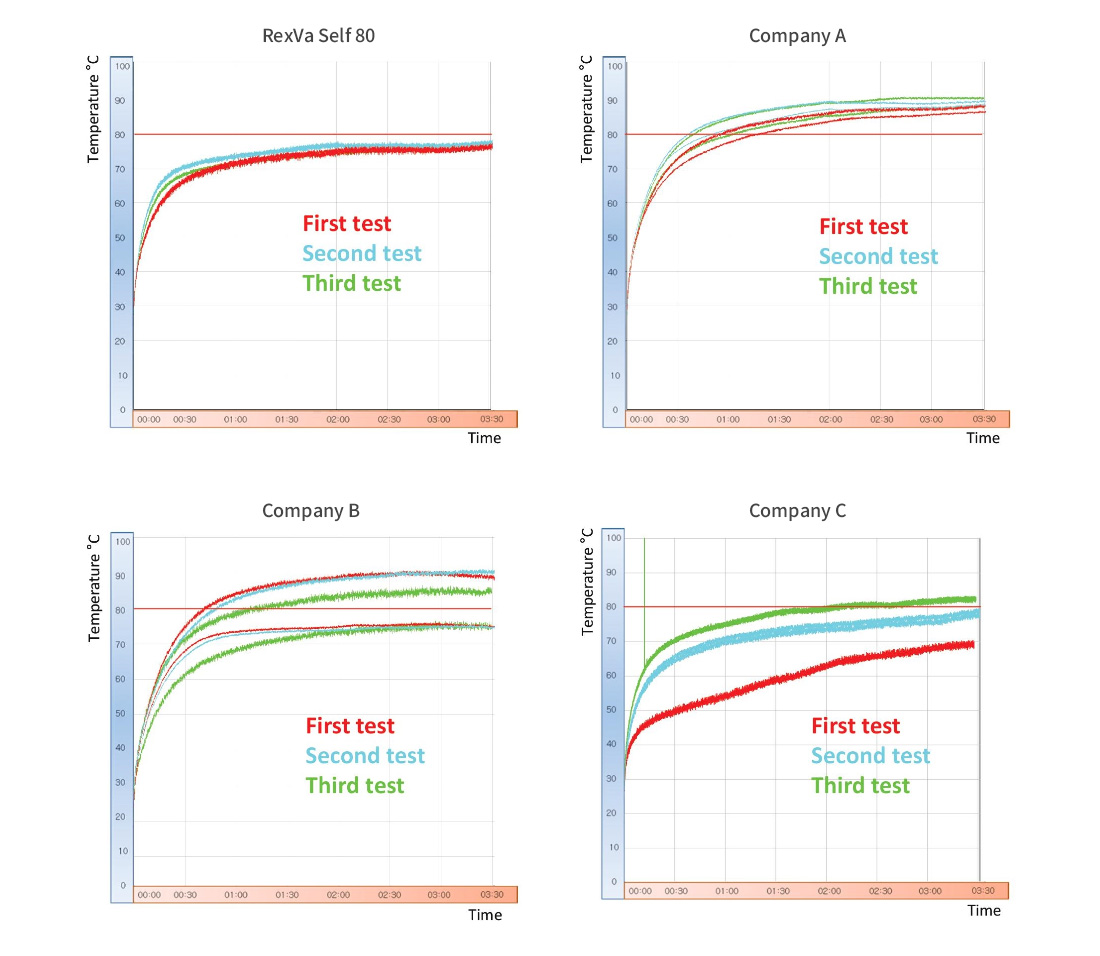

Local overheating comparative test

The purpose of the test:

Testing method

Test results:

Reasons for the success of the Rexva Self80 heating film

Measurement results:

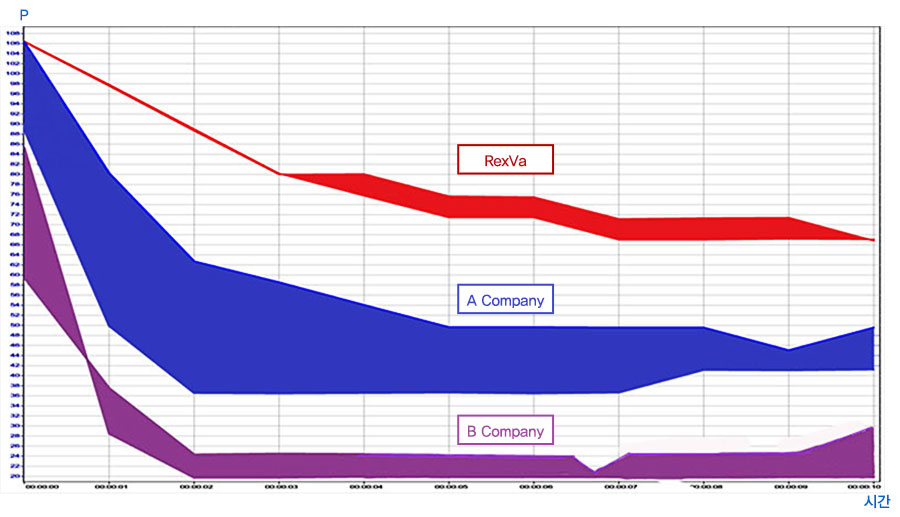

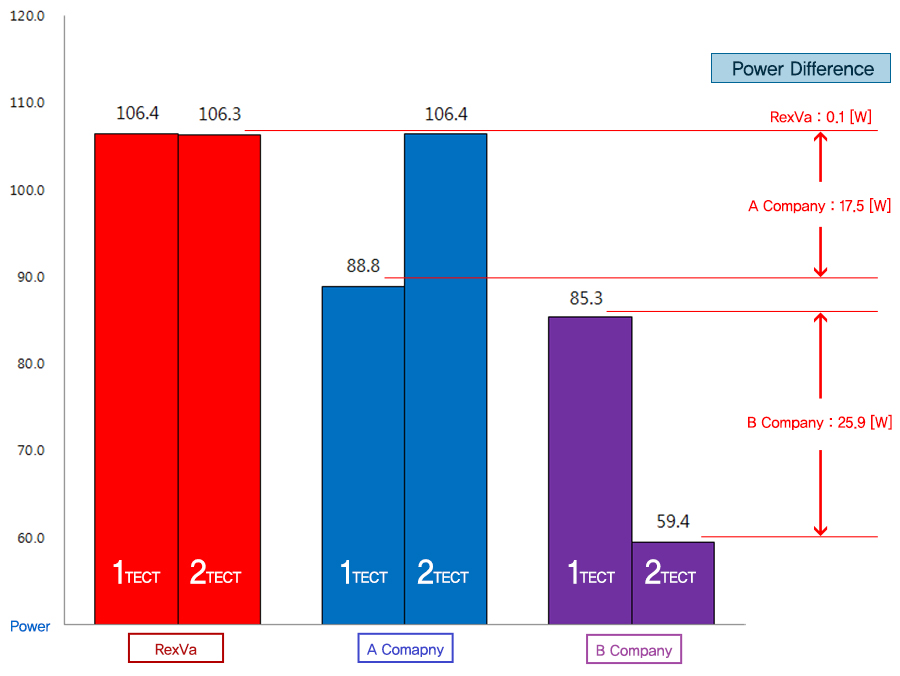

The Power change Graph of Energy Saving PTC Heating Film

The Power(Watt) recovery graph of Energy Saving PTC heating Film

| Number of Test | RexVA | A Company | B Company |

| Primary | 106.4 | 88.8 | 85.3 |

| Secondary | 106.3 | 106.4 | 59.4 |

| Power difference value | 0.1 | -17.5 | 25.9 |

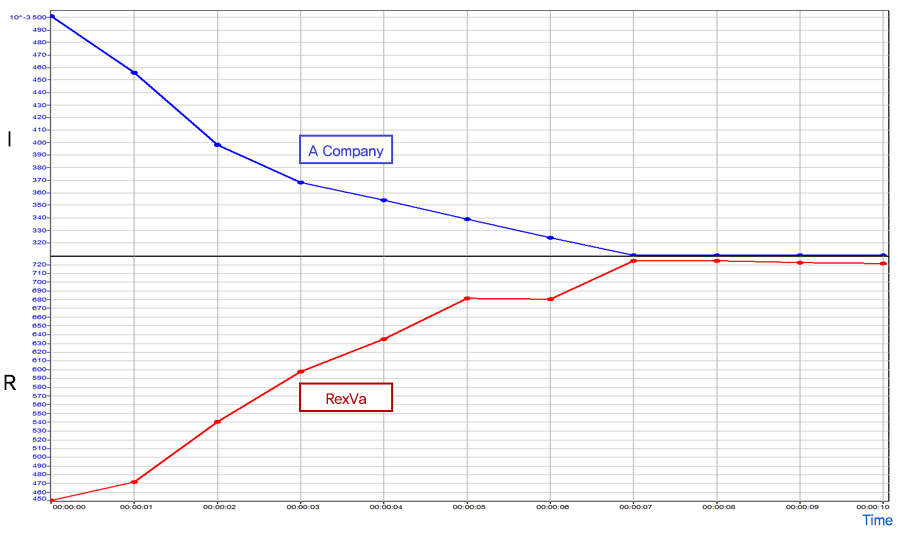

The Graph of Energy Saving PTC currency and resistance change

The Graph of Change of Currency and Resistance Compared with Competitors

| Start | End | Change Ratio | |

| Currency | 0.4861 | 0.3105 | 56.6% |

| Resistance | 441.4 | 723.4 | 63.8% |

| Temperature | 28.46 | 113.47 |

| Start | End | Change Ratio | |

| Currency | 0.5006 | 0.31 | 61.4% |

| Power | 106.44 | 67.11 | 58.6% |

| Resistance | 450.6 | 721.6 | 60.1% |

| Temperature | 22.12 | 113.04 | |

| The Resistance Recover Ration | 450 | 446 | 0.8% |

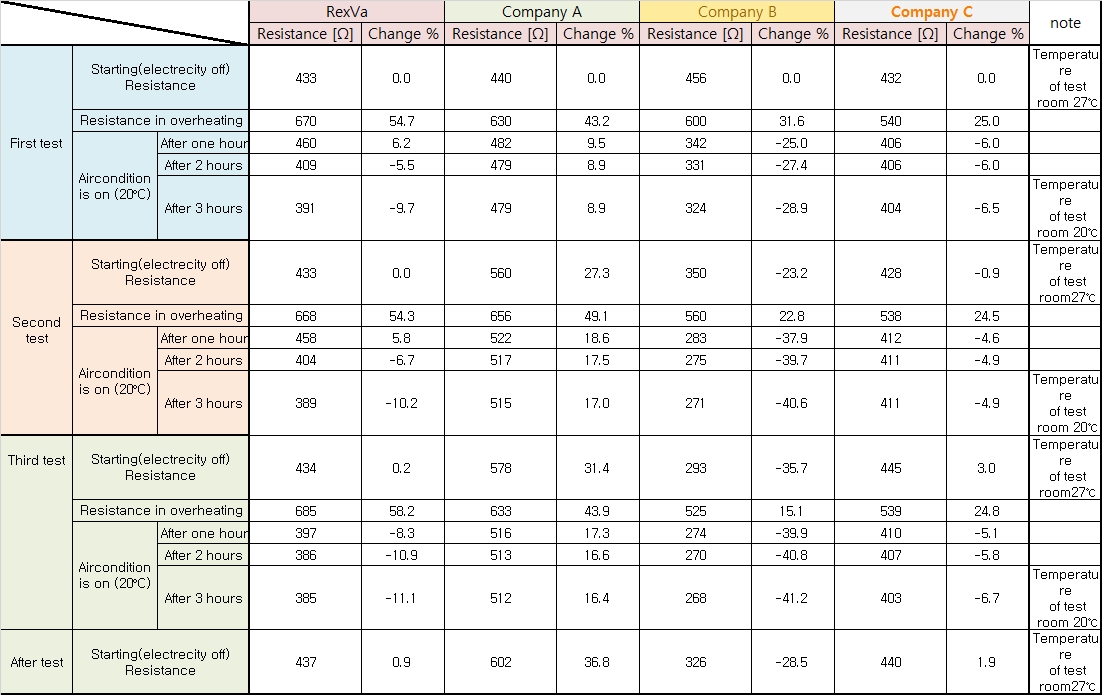

The test result of resistance change of Energy Saving PTC

| Company Index | Initial Value | After primary heating | After secondary heating | |||||||

| Resistance(A) | Watt/1m(B) | Resistance(C) | Power(Watt/1m : D) | Resistance(A-C) | Power Difference (Watt/1m : B-D) |

Resistacnce(G) | Power (Watt/1m : H) |

Resistacnce(A-G) | Power Difference (Watt/1m : B-H) |

|

| RexVa | 450 | 108 | 447 | 108 | 3 | 0.7 | 466 | 109 | 4 | 1.0 |

| A Company | 407 | 119 | 377 | 128 | 30 | 9.5 | 392 | 123 | 15 | 4.6 |

| B Company | 445 | 109 | 760 | 64 | 315 | 45.1 | 662 | 73 | 217 | 35.7 |

| C Company | 496 | 98 | 442 | 110 | 54 | 11.9 | 399 | 121 | 97 | 23.7 |

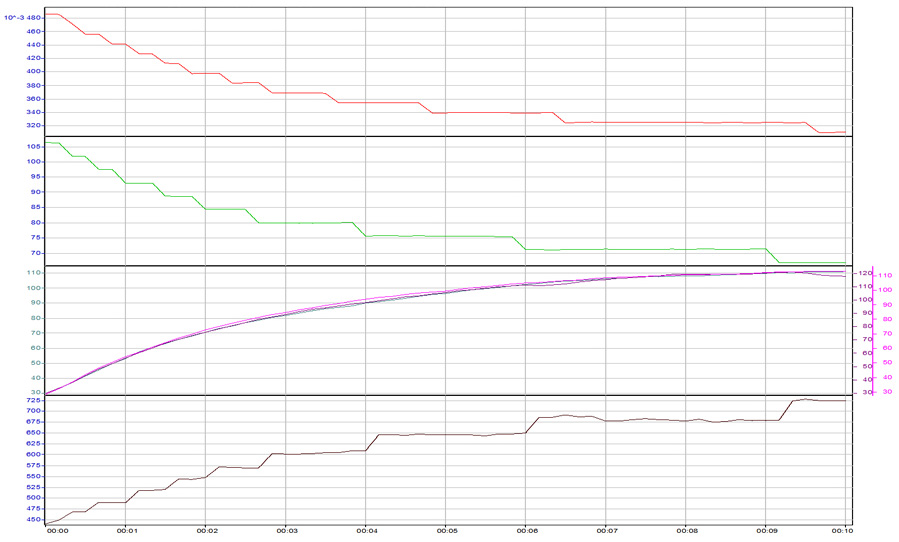

Energy Saving PTC Performance Test

| Watt | I | Time |

| 99 | 0.45 | 0 : 00 |

| 96.8 | 0.44 | 0 : 13 |

| 94.6 | 0.43 | 0 : 26 |

| 92.4 | 0.42 | 0 : 35 |

| 90.2 | 0.41 | 0 : 41 |

| 88 | 0.4 | 0 : 50 |

| 85.8 | 0.39 | 1 : 05 |

| 83.6 | 0.38 | 1 : 12 |

| 81.4 | 0.37 | 1 : 25 |

| 79.2 | 0.36 | 1 : 40 |

| 77 | 0.35 | 1 : 51 |

| 74.8 | 0.34 | 2 : 06 |

| 72.6 | 0.33 | 2 : 22 |

| 70.4 | 0.32 | 2 : 35 |

| 68.2 | 0.31 | 3 : 06 |

| 66 | 0.3 | 3 : 32 |

| 63.8 | 0.29 | 4 : 05 |

| 61.6 | 0.28 | 4 : 56 |

| 59.4 | 0.27 | 6 : 00 |

| 57.2 | 0.26 | 8 : 07 |

| 55 | 0.25 | 10 : 00 |

| Change Ratio of Power | 80% | |

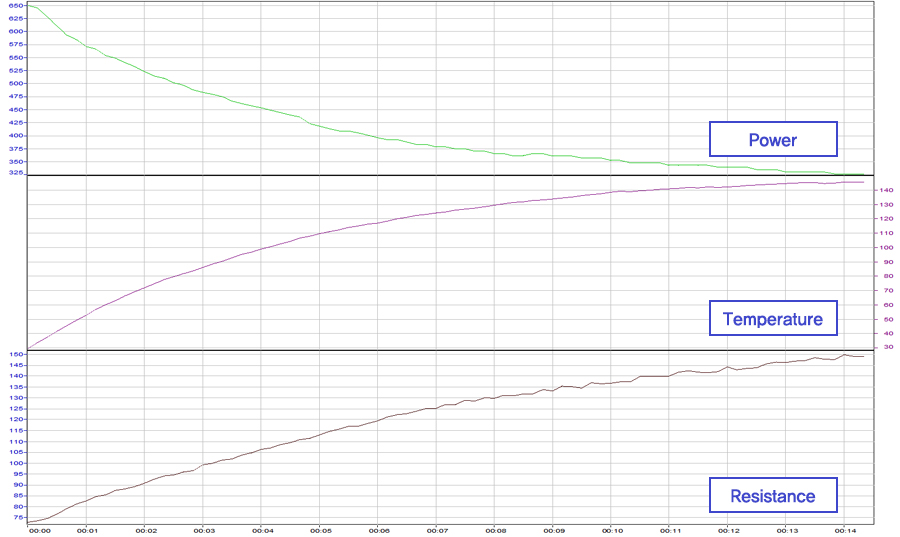

The Energy Saving PTC Efficiency Test (Currency, Resistance, Temperature change ratio)

| Start | Finish | Change Range | Percent | |

| Resistance | 72.83[Ω] | 149.18[Ω] | 76.35 | 104.8[%] |

| Power | 649.6[W] | 326.4[W] | -323.2 | 99[%] |

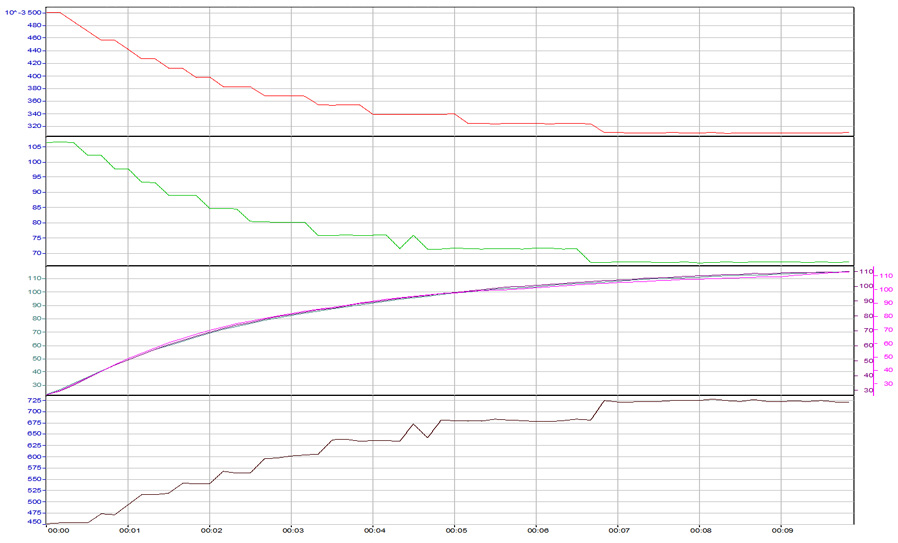

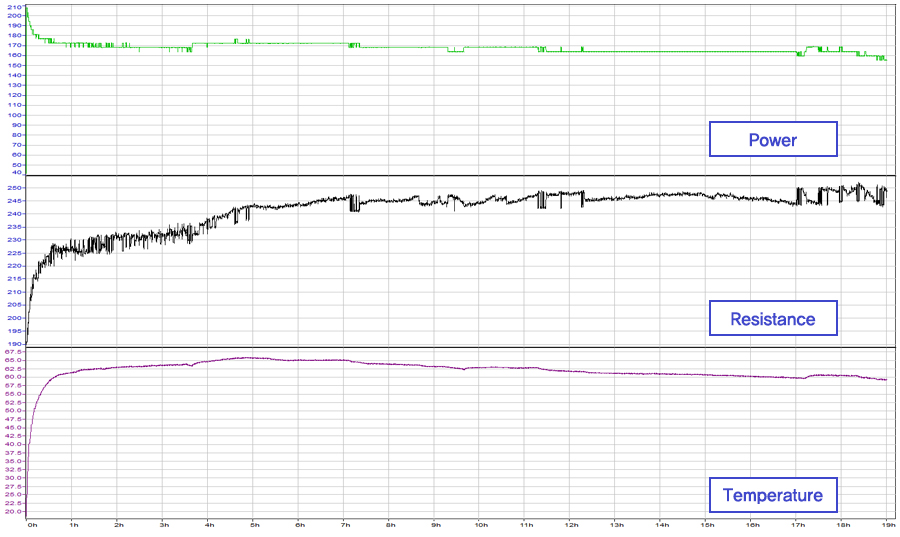

Test of Overheating for Energy Saving PTC in ordinary method installation

| Start | Finish | Change Range | |

| Resistance | 190.78[Ω] | 249.42[Ω] | 59.31 |

| Power | 209.5[W] | 155.42[W] | -54.08 |

| Surface Temp. | 24.87[℃] | 59.19[℃] | 34.73 |

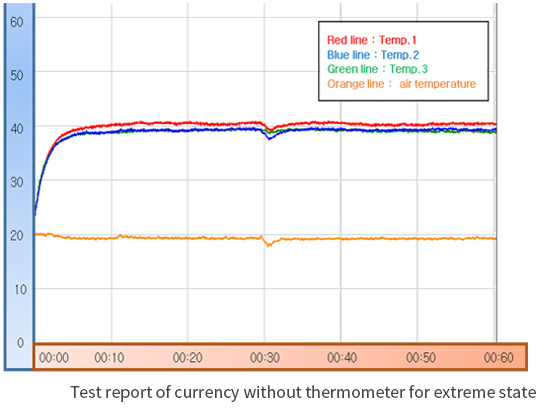

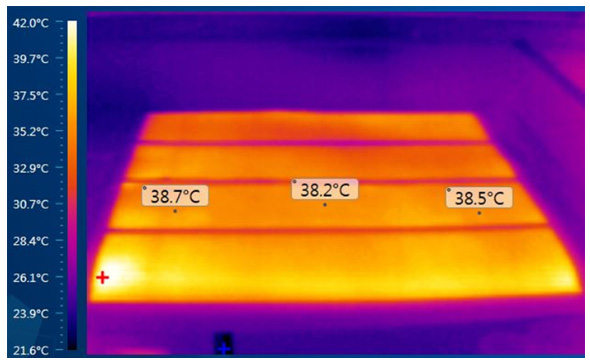

Energy Saving PTC heat dispersion test report

Normal heating film has tendency for central overheating so center has the highest temperature. Heat dispersion test shows central heat is lesser than left and right temperature so it reduces the danger factor due to centralized heat.

Normal heating film has tendency for central overheating so center has the highest temperature. Heat dispersion test shows central heat is lesser than left and right temperature so it reduces the danger factor due to centralized heat.

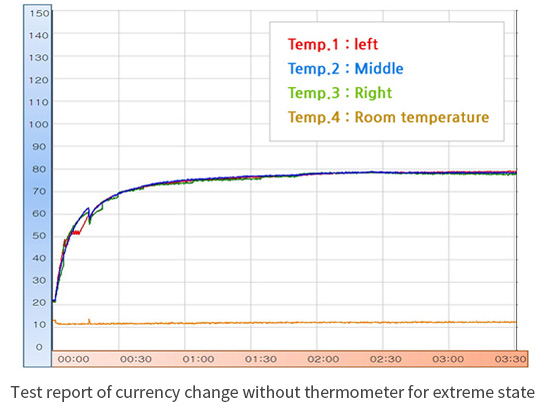

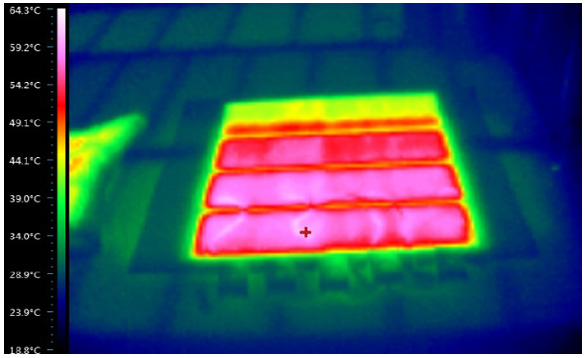

Energy Saving PTC heating film heat dispersion picture test report

Energy Saving PTC heating film dispersing heat when overheated picture test report

Normal heating film has tendency for central overheating so center has the highest temperature. Heat dispersion test shows central heat is lesser than left and right temperature so it reduces the danger factor due to centralized heat.

Energy Saving PTC Product Comparison Data

| Division | General Product | PTC Product |

| Resistance and Watt | same | same |

| Heat-generating temperature and speed | There is a difference depending on the atmospheric temperature, but the heating rate is fast | When the general product sets up 100% calescence, PTC heating film products is climbing steadily by 30℃ (70%) |

| Film surface temperature with the passing of one hour |

Heating film is at ambient temperature 22℃, heating film surface temperature designed as a 40~45℃. At ambient temperature over 22 ℃, heating film surface temperature is also rising sharply. If the surface is covered with carpet for a long time,local overheating phenomena occurs. |

In the atmosphere temperature in about 15℃, the resistance change and a temperature goes up. In the atmosphere temperature in more than 22℃, the surface temperature of heating film stands up 35℃. The overheated inside in local overheating reaches 60℃. The amount of electricity used depending on electricity of heating film and local overheating area decrease in 10~30% and prevents over temperature. If an overheating occur in the pressure in a long time or heat collection, the temperature increase in more than 80~100℃ according to original scheme power value. |

| Variation rate of resistance (shut off the power supply) | It restores at the original value with the passing of one hour. | After 24 hours, restoration of the original resistance value |

| Shut off the power supply(with the passing of one hour) | Beginning of the original value | Beginning of the changed resistance value |

| Actuating power heating time(as one hour passes) | After a primary test, the same of heating temperature | The resistance value comes out above the initial resistance value. So the power consumption is reduced and the surface temperature after an hour the same. |

| Result | Average resistance value standard(same as general ,PTC) 50width 1M standard-440Ω(110W) 80width 1M standard-250Ω(190W) 100width 1M standard-210Ω(230W) |

PTC products have a heat slower than regular products. It is characteristic of the PTC product to reduce local overheating. |

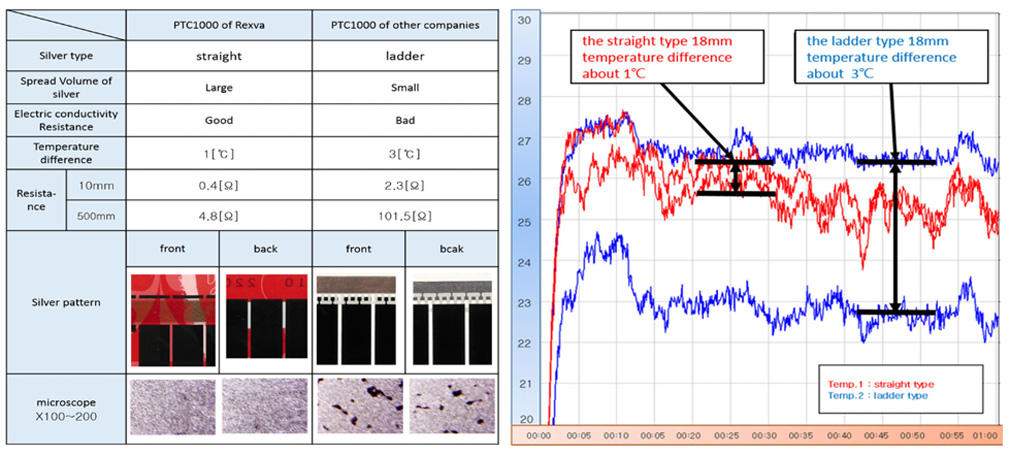

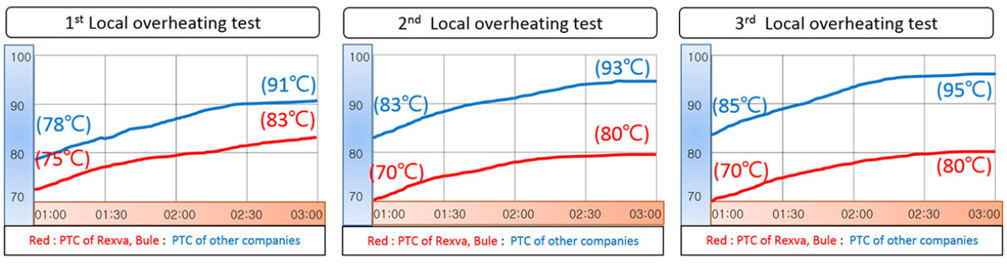

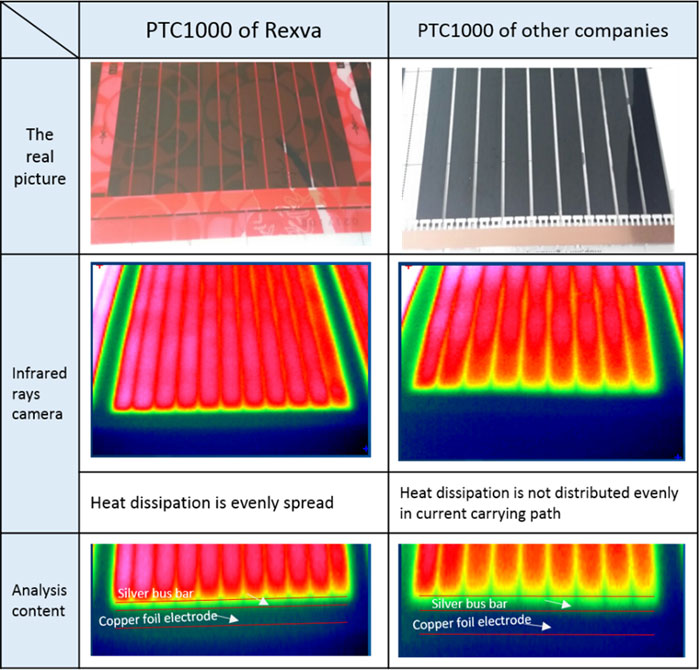

Compare PTC1000 Products of Local Overheating Test with those of other companies

The excellence of Rexva's PTC Heating Film

| Article | Rexva | Other companies |

| Overheating temperature control | Control below 85℃ | Control below 95℃ |

| Heat dissipation effect | Even heat | High temperature of energized part |

Temperature Control of Local Overheating

| Division | Count | Beginning(℃) | After an hour(℃) | After 3 hours(℃) | Temperature difference(℃) |

| Rexva | 1st | 29 | 75 (70~80) | 83 (75~90) | 8 |

| 2nd | 29 | 70 (60~80) | 80 (70~90) | 10 | |

| 3rd | 29 | 70 | 80 | 10 | |

| Other companies | 1st | 27 | 78 (73~83) | 91 (85~97) | 8 |

| 2nd | 27 | 83 (80~85) | 93 (85~100) | 10 | |

| 3rd | 27 | 85 (80~90) | 95 (90~100) | 10 |

Product Comparison

| Division | Rexva | Other Companies |

| Sample | PTC1000 | PTC1000 |

| Length | 1000[mm] | 1000[mm] |

| Width | 1000[mm] | 1000[mm] |

| Resistance | 215[Ω] | 225[Ω] |

| Watt | 225[w] | 215[w] |

| Sliver type | Straight | Ladder |

| Temperature difference | 1℃ | 3℃ |

| Test conditions | Measuring device : wt200, signasoft6000 Measurement time : 3 hours Environmental temperature : 26~28℃ |

|

Heat Dissipation Effect

Characteristics by Sliver Type